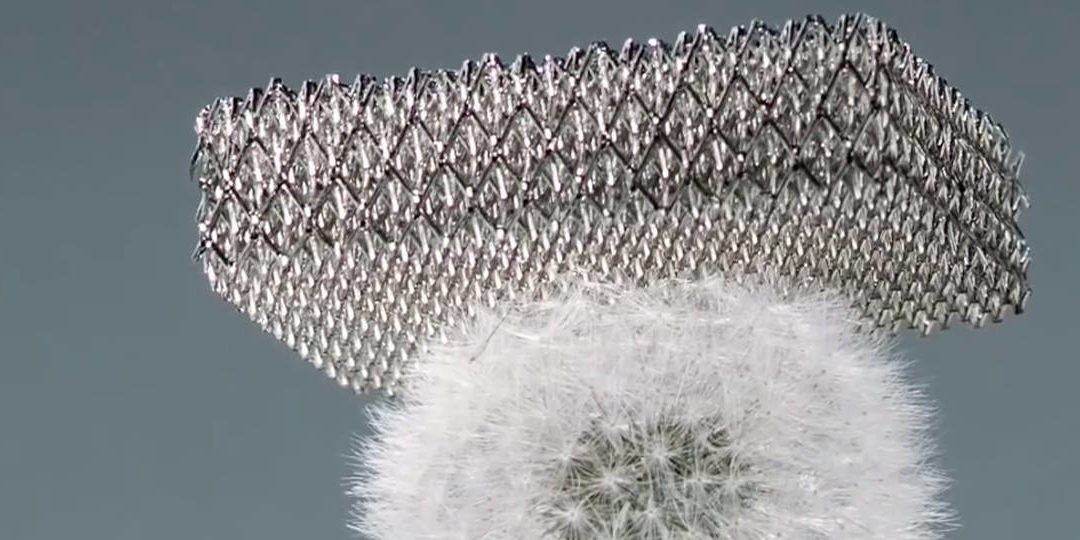

The material is a structure created from 3D microlattice with microscopic hollow tubes with a thickness equivalent to 1/1000 of a human hair. In this video released by the organization, researcher Sophia Yang compared it with bone tissue; that is, a porous, lightweight and sturdy material. “The bone structure is very rigid, but its interior is practically hollow and open at the cellular level so that the bones do not break, while having a lighter structure,” said Yang, according to whom microlattice is one of the lightest materials known to science.

Microlattice is incredibly light, and consists of 99.99% air. This feature is clearly illustrated in the picture above, where investigators put a piece of the material on a dandelion. However, the interconnected tubes would give enough strength to support the weight of heavy metals and plastics used in the manufacture of aircraft strength. According to the group of scientists, the resulting material is 100 times lighter than polyurethane foam.

The material is also highly resistant to impact, because it naturally recovers its initial shape even after being compressed. The conclusion is that this feature is ideal for absorbing energy or mechanical impact.

Researcher Sophia Yang indicates that this new material can be used to make lighter planes with better fuel utilization. In principle, the material could be used inside doors, floor panels and overhead luggage compartments. The group of scientists also considered the feasibility of its use in aircraft structural components.